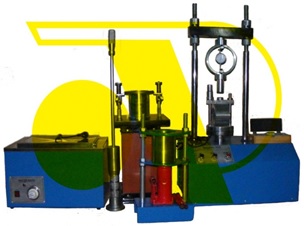

ASPHALT EQUIPMENT

This equipment is intended to meet the standard of the Marshall test, which is the method covers the measurement of resistance to plastic flow of cylindrical speciment of bituminous paving mixture loaded on the lateral surface by means of the Marshall apparatus. This test method is for use with mixtures containing asphalts cement and aggregate up to 11/2 in. (37.5 mm) nominal maximum size.

Consists Of:

Compression Machine Steel frame electric, 220 V-AC,

1/2 HP 1 Phase, speed : 2″ per-minute. –> 1 set

Standard Compaction Mold 4″ dia. Machined steel, galvanized,

4″dia., 3″ height, with collar and base plate. –> 1 set

Modified Compaction Mold 6″ dia. Machined steel, galvanized,

6″dia., 4,5″ height, with collar and base plate. –> 1 set

Stability Mold 4″ dia. (breaking head) Cast alumunium,

split type 6″ i.d., 4″ wide –> 1 set

Stability Mold 6″ dia. (breaking head) Cast alumunium,

split type 6″ i.d., 4″ thick and 6″ nominal wide. –> 1 set

Compaction Hammer Machine steel, plated 10 lbs,

hammer weight, 18″ drop height. –> 1 set

Compaction Pedestal Wooden base 8″ x 8″ (0.67 to 0.77 kg/cm3)

with steel platen 12″ x 12″ –> 1 set

Compaction Mold Holder Machine steel, quick clamping

system for 4″ and 6″ i.d mold –> 1 set

Specimen Extruder Steel frame, hydraulic system, available for 4″

and 6″ dia. Mold samples –> 1 set

Flow Meter Cast alumunium, clamping bolt, with digital indicator

range up to 30 mm and accuracy 0.01 mm –> 1 set

Water Bath Stainless steel, water heater, 220 V-AC thermostat 30 – 85 deg.C –> 1 set

S-type load cell 50 kN capacity available for any catergory asphalts mixing test. -Environmentally Protected to IP67 -All Stainless Steel for industrial Environments -Calibration Certificate Supplied –> 1 set